We offer end to end production, development, and support for the client’s transcatheter heart valves. Part of our service is making sure that the client’s animal tissue derived heart valve stays functional longer by treating the tissue with an anti-calcification treatment.

The longevity of transcatheter heart valves is important, particularly if younger patients will eventually be considered. Durability is determined by numerous factors including the characteristics of the tissue, tissue treatments, valve design, symmetric leaflet coaptation, patient age & other factors.

Calcium build-up in the tissue causes the valve to become rigid and reduces function. Mechanical stress and collagen fibers disruption of the prosthetic leaflets may favor early calcification of the leaflets and valve degeneration. One can avoid valve degeneration through effective Anti-Calcification treatment of the tissue leaflets.

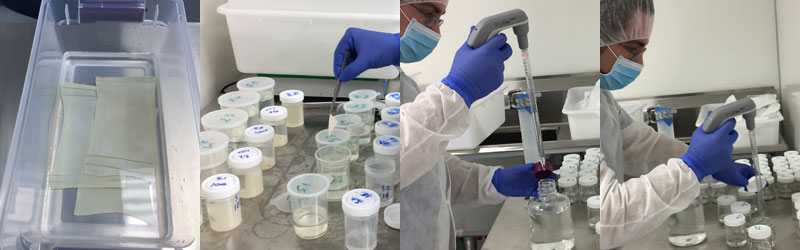

We offer an end to end anti-calcification process: From design to formulation & transfer

We design anti-calcification solution formulatons for the client to maximize calcification resistance in valve tissue.

Design SOPs and work instructions to optimize the process of anti-calcification treating fixed tissue.

Coordinate animal testing necessary for the client, both large and small.

We coordinate valve durability testing to ensure the new process adds value to the client’s valve.

We can help the client set up a new lab, or modify an existing one to accommodate the new anti-calcification treatment with equipment, solutions, and personnel training.

We offer all the training necessary to the personnel to conduct anti-calcification at client site.

BMSI can work with their clients to integrate an anti-calcification process into their new or existing tissue processing treatment.

Because quality and attention to detail are of utmost importance at BMSI – we have always been successful in producing anti-calcification treatments that work